Ever faced a shipment of bandage dresses with glaring flaws?

It’s a nightmare that can sink your business fast.

Poor quality turns a profitable deal into costly returns and angry customers.

To ensure quality for bandage dress imports, essential QC checks include verifying consistent sizing, durable fabric, and flawless stitching.

Implementing pre-production, in-line, and final random inspections helps identify and rectify issues early.

Additionally, working with factories that have robust internal quality management systems is crucial for maintaining high standards.

Keep reading to uncover practical QC strategies for your bandage dress imports.

These methods will help your business stand out and ensure every shipment meets your high standards.

Why Are Pre-Shipment QC Checks Crucial for Bandage Dress Imports?

Have you ever received a shipment only to find half the order unusable?

It’s a frustrating reality for many importers of bandage dresses.

Without early checks, small issues can become costly disasters.

Pre-shipment quality control checks are crucial for bandage dress imports to prevent costly defects before goods leave the factory.

These inspections confirm product specifications, identify manufacturing errors, and ensure compliance with quality standards.

By catching issues early, businesses avoid financial losses from returns and protect their brand reputation, ensuring delivered products meet expectations.

To tackle these challenges successfully, you need effective quality control.

Let’s dive into practical strategies and key considerations to ensure every bandage dress shipment meets your standards.

Why Early Detection Matters for Bandage Dress Imports

Ensuring the quality of imported bandage dresses before they leave the factory is critical.

This proactive approach saves costs and protects your brand’s reputation.

Addressing potential issues early on prevents financial losses and maintains customer satisfaction.

- Cost Efficiency: Spotting defects at the factory level avoids the expense of transporting substandard bandage dresses.

Why pay shipping for items you’ll have to return or discard?

This step cuts financial losses significantly and keeps your budget intact. - Customer Satisfaction: Early checks reduce return rates by ensuring only quality products reach your clients.

Negative feedback can sink a brand, especially in markets like North America or Europe.

Protect your reputation by addressing issues upfront.

Once you understand the importance of early detection, knowing what to look for is key.

A thorough pre-shipment inspection covers several vital aspects of your bandage dress order.

This meticulous process ensures that every item meets your standards.

Key Areas for Pre-Shipment Inspection of Bandage Dresses

A comprehensive pre-shipment inspection is crucial for importing bandage dress.

It ensures product quality and order accuracy.

Focusing on key areas helps mitigate risks and uphold your brand’s standards.

- Quantity Verification: Ensure the exact number of bandage dresses matches your order.

Discrepancies can disrupt inventory and sales plans.

A quick count at the factory prevents shortages or overages upon arrival. - Initial Visual Checks: Scan for obvious damage, defects, or incorrect items before packing.

Look for fabric tears or color mismatches in your bandage dress batch.

This simple step avoids surprises when unboxing in your warehouse.

To wrap up, pre-shipment QC is your first defense against quality issues.

It sets the tone for a smooth import process and ensures you start on the right foot with your bandage dress supplier.

What Are the Critical QC Checks During Bandage Dress Production?

Did a batch of bandage dresses ever arrive with uneven seams or fabric that fades after one wash?

It’s a common pitfall when production isn’t monitored. Mid-process checks can prevent these issues.

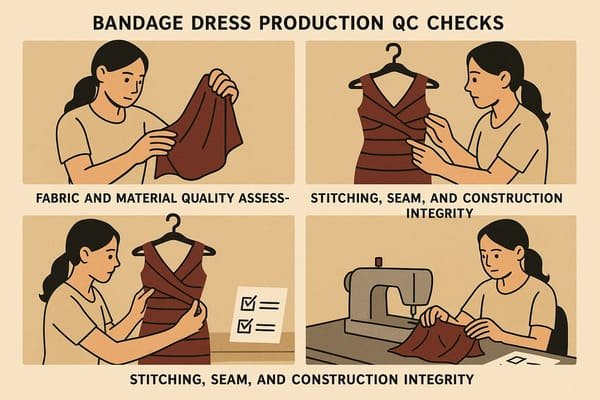

Critical QC checks during bandage dress production include inspecting fabric quality for consistency, verifying stitching integrity and seam strength, and ensuring accurate sizing.

These in-process evaluations identify deviations early, allowing for immediate corrective actions.

This minimizes defects and ensures adherence to design specifications before final assembly.

Quality materials and expert construction are the backbone of any great bandage dress.

By focusing on these initial assessments, we lay the foundation for a well-made garment.

Close attention to these details prevents issues and ensures satisfied customers.

Fabric and Material Quality Assessment for Bandage Dresses

The quality of fabric and materials is paramount for bandage dresses.

It dictates both fit and longevity.

A thorough assessment ensures the garments meet specifications and customer expectations, preventing future disappointments.

- Composition & Stretch: Verify the fabric matches your agreed specifications.

Test the stretch and recovery of the material, as these are crucial for a figure-hugging bandage dress.

Without proper elasticity, the fit fails to deliver. Ensure the supplier uses the right blend for durability. - Weight & Colorfastness: Check the fabric weight to confirm it meets quality benchmarks.

Test for color bleeding or fading to avoid issues after washing.

A reliable bandage dress factory will provide samples for these checks.

This prevents customer dissatisfaction down the line.

Beyond the fabric itself, the construction of the bandage dress is equally vital.

Examining the stitching, seams, and overall build quality ensures durability and a flawless finish.

This attention to detail reflects the garment’s overall integrity and quality.

Stitching, Seam, and Construction Integrity in Bandage Dresses

Examining the stitching, seams, and overall construction is crucial.

These elements determine a bandage dress’s durability and finish.

Meticulous inspection ensures each garment meets high-quality standards.

- Even & Secure Stitching: Inspect all seams for consistent, tight stitching.

Look for loose threads or skipped stitches that could unravel over time.

A high-quality bandage dress wholesaler prioritizes durable seams to ensure longevity.

Weak stitching leads to returns and complaints. - Zipper & Hardware Functionality: Test zippers for smooth operation and check clasps or hooks for secure attachment.

Faulty hardware can render a dress unusable.

Make sure every piece functions as expected to uphold your brand’s standards.

In short, monitoring production QC guarantees that every stitch and material aligns with your vision.

It’s a proactive step to deliver flawless bandage clothing to your clients.

How to Ensure Post-Production QC for Bandage Dress Imports?

Ever unboxed a shipment of bandage dresses to find sizes that don’t match your charts?

Post-production QC is your final checkpoint to avoid such shocks. It ensures the finished product is ready for market.

To ensure post-production QC for bandage dress imports, focus on final garment inspection, verifying measurements against size charts, and assessing overall fit.

Check for fabric imperfections, proper stitching, and correct labeling.

Finally, review packaging to confirm it protects the garments during transit, preventing damage and maintaining presentation.

A perfect fit defines a bandage dresses, so inconsistent sizing can deeply frustrate customers and harm sales.

Therefore, careful attention to measurements and overall garment shape is essential.

Sizing and Fit Consistency for Bandage Dresses

Consistent sizing and an accurate fit are critical for bandage dresses.

Discrepancies can lead to customer dissatisfaction.

Verifying measurements ensures that every garment provides the desired silhouette and comfort.

- Measurement Verification: Measure key points of a sample range against your size charts.

Check bust, waist, and hip dimensions to ensure consistency across the batch.

A top-tier bandage dress manufacturer will align with your specs.

This prevents ill-fitting garments from reaching your shelves. - Proportionality Check: Assess the overall garment shape to confirm it contours correctly to the body.

The flattering fit of a bandage dress is its selling point.

Ensure proportions match the intended design for a polished look every time.

Once the bandage dresses themselves pass inspection, attention must turn to how they are presented and protected.

Proper packaging and accurate labeling are essential for efficient handling and successful delivery.

This final check ensures everything is for shipment.

Packaging and Labeling Accuracy for Bandage Dress Shipments

Accurate packaging and labeling are crucial for bandage dress shipments.

They ensure compliance and protect the garments during transit.

Verifying these details prevents delays and maintains customer satisfaction upon arrival.

- Correct Labeling: Verify internal labels for care instructions, material composition, and country of origin.

Ensure they’re accurate and securely attached to meet import rules.

A fashionable bandage dress factory will prioritize compliant labeling.

Errors here can delay shipments at customs. - Secure & Compliant Packaging: Confirm each dress is individually packed in poly bags with hang tags attached.

Check exterior carton markings for accuracy in shipping and inventory tracking. This keeps your order safe and organized during transit.

By meticulously checking sizing, fit, labeling, and packaging, you can ensure your bandage dress imports meet high standards.

These steps are crucial for customer satisfaction and avoiding costly returns.

A thorough final inspection process is key to a smooth and successful import experience.

What Special QC Considerations Apply to Bandage Dresses?

Curious why some bandage dresses lose shape after one wear?

Their unique design demands specific checks beyond standard clothing QC.

Overlooking these can compromise the product.

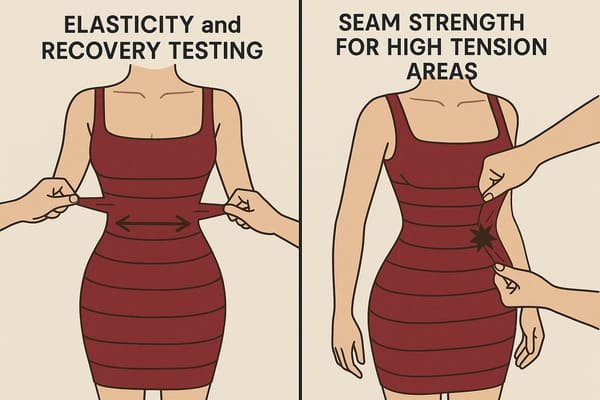

To ensure quality control for bandage dresses, special considerations apply due to their unique fabric and body-contouring fit.

Focus on elasticity retention, seam integrity under tension, and consistent compression.

Verify the material’s ability to recover shape and ensure all seams are robust.

These specific checks prevent garment distortion and maintain the desired silhouette.

A bandage dress’s perfect fit hinges on its fabric’s stretch and form retention.

That’s why the material’s ability to "snap back" is critical: it prevents sagging and ensures both lasting appearance and wearability.

Elasticity and Recovery Testing for Bandage Dresses

Elasticity and recovery are fundamental to a bandage dress’s appeal.

The fabric must stretch to contour the body perfectly.

It should also retain its original shape after wear, preventing distortion.

- Stretch Retention: Test the fabric to ensure it maintains elasticity and “snap-back” quality over time.

A bandage dress must hug the figure without sagging after wear.

Conduct stretch tests to confirm the material holds up under repeated use. - Compression Integrity: Verify the fabric offers the right level of compression without feeling restrictive.

It should retain its form after stretching.

A versatile bandage dress supplier will prioritize this balance to guarantee comfort and style in every piece.

For a garment to truly last, its construction must be robust, particularly in high-tension areas.

These critical points are what determine the bandage dress’s overall durability and longevity.

Seam Strength for High Tension Areas in Bandage Dresses

Seam strength is vital for bandage dresses, especially in high-tension areas.

Well-constructed seams prevent rips and ensure longevity.

This attention to detail contributes significantly to garment durability.

- Reinforcement Check: Focus on high-tension areas, such as the hips, bust, and waist.

Ensure seams are reinforced to withstand pressure from the stretch fabric.

A sophisticated bandage dress manufacturer knows these zones need extra care to prevent splits. - Durability Assessment: Perform pull tests on critical seams to evaluate strength.

This prevents tearing during wear, especially for active use at parties or events.

Strong seams are crucial for maintaining the lasting quality of bandage clothing.

Ultimately, these specialized checks ensure your bandage dresses stand out for quality.

They address the unique demands of this style to keep customers satisfied.

How to Partner Effectively for Bandage Dress QC?

Struggling to maintain consistent quality with your bandage dress imports?

Partnering strategically can make all the difference.

The right collaboration ensures flawless products.

To partner effectively for bandage dress quality control, establish clear communication with your manufacturing partner regarding specifications.

Implement transparent inspection protocols at each production stage, from fabric sourcing to final assembly.

Utilize third-party quality assurance services for unbiased assessments and compliance checks.

This collaborative approach ensures consistent product quality and minimizes defects.

A strong manufacturing partnership is crucial for bandage dress QC.

Begin by establishing clear guidelines and expectations to ensure everyone aligns with your quality standards.

Working with Your Bandage Dress Supplier on QC Protocols

Ensuring high-quality bandage dresses requires a strong partnership with your supplier.

Clear communication and defined standards are essential for successful production.

This collaborative approach minimizes issues and guarantees customer satisfaction.

- Clear Standards & Communication: Define detailed quality benchmarks upfront with your innovative bandage dress supplier.

Formalize these in a QC agreement covering fabric, fit, and finishing.

Share expectations early to avoid misunderstandings during production. - Sample Approval Process: Implement a strict process for approving pre-production and during-production samples.

Review each sample against your specs to ensure ongoing adherence.

This step keeps your custom bandage dress order on track at every stage.

Even with robust internal protocols, external verification adds another layer of security.

Independent checks provide impartial assessments. This ensures your imports consistently meet desired quality levels.

Leveraging Third-Party Inspection for Bandage Dress Imports

To further strengthen quality assurance, consider independent third-party inspections.

These services offer an objective perspective on your production.

They help ensure your bandage clothes meet all specified standards before shipping.

- Unbiased Assessment: Hire independent QC agencies in China for thorough inspections.

They provide objective evaluations, especially useful if you lack an on-ground presence.

A global bandage dress wholesaler benefits from expert eyes catching hidden flaws. - Risk Mitigation: Use third-party services to verify quality at key stages before shipment.

They reduce the risk of receiving substandard goods, saving you from costly returns.

This builds confidence in your bandage dress supply chain.

Focusing on detailed specifications and sample approvals with your production partner, alongside integrating independent inspection services, significantly enhances quality control.

This comprehensive strategy helps ensure every bandage dress meets high standards.

Conclusion

Navigating quality control for bandage dress imports from China doesn’t have to be daunting.

With the right QC checks, you can ensure top-notch products that boost customer satisfaction and protect your brand.

For more insights and support, explore our homepage and reach out via our contact page.

As a dedicated supplier at Fangbei, we’re here to help your business succeed.